| Depth Of Field: | 50mm | Min. Laser Width: | 40mm |

|---|---|---|---|

| Max. Laser Width: | 50mm | Standard Working Distance: | 115mm |

| Sanning Single Line Density: | 768points/line | Scanning Measuring Speed: | 10752points/sec |

| Scanning Measuring Accuracy: | 25 Um | Scanning Measuring Min. Points Distance: | 0.06mm |

3D Coordinate Measuring Machine Laser Scanner Reverse Engineering

3D image measuring

Comparing to the traditional 2D image measuring, the 3D image measuring is able to measure the 3D edge contour and the 3D features, it is a revolutionary development in the contour measuring area.

Principle

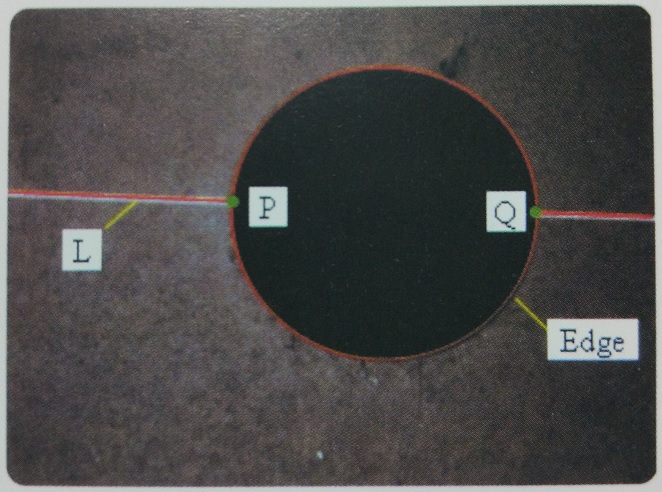

The LSP50 laser Hiscanner calculates the edge point of the object via the crossing of the 2D image contour and the laser line projecting on the object.

As the sample shown below, the software detect the image edge of the circle through image processing, and the laser line center L is crossing the circle, which create 2 points P, Q.

Parameters

Depth of Field: 50mm

Minimum laser width: 40mm

Maximum laser width: 50mm

Standard Working Distance: 115mm

| Model | LP550 | ||

| Weight | 390g | Scanning measuring speed | 10752points/sec |

| Dimension | 145*110*45mm | 3D image measuring speed | 1 time/sec |

| Adaptor | M8, PAA1 | Scanning measuring accuracy | 25 um |

| Depth of field | 50mm | 3D image measuring accuracy | 20 um (clear edge contour) |

| Min. laser width | 40mm | Scanning measuring min. points distance | 0.06mm |

| Max. laser width | 50mm | Laser level | Level 2(Visible red light) |

| Standard working distance | 115mm | Laser wavelength | 650nm |

| Sanning single line density | 768points/line | Working temperature | 10-40°C |

Notice: The 3D image measuring has high requirement of the surface of the measuring object, the object of light color and matte finish can be directly measured, for example gyp or wood, other objects require the surface process.

Reverse engineer

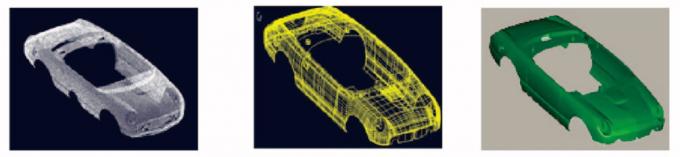

Users are able to get clear and accurate edge data of the object via 3D image measuring function, offering reliable data for reverse engineering processing. Combining 3D image measuring function and laser scanning measuring function is able to gain complete curve information, edge data and the holes features data on the object.

Points group results after scanning Capturing the curve of the objects Create a 3D drawing with 3D software as Pro/E, UG