| Control Mode: | Full CNC Close-loop Motion Control | CCD: | Industrial Color 1/3″ CCD Camera |

|---|---|---|---|

| Lens: | Manual Dented Zoom Lens 0.7 – 4.5X (Navitar Zoom Lens For Option) | Resolution: | 1um, 0.5um For Option |

| Motion Control And Illumination: | UWC VMM Control Package | Power Supply: | 220V±10% AC 50Hz, Resistance≦4 Ohm Ground Should Be Required |

| Operation Mode: | Integrated Intelligent Control(joystick, Mouse, Keyboard) |

Full-Automatic CNC Vision Measurement machine 3D measuring Laser Scanning

Standard Series Automatic Vision Measurement Machine

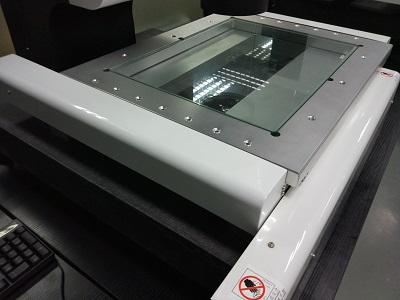

Standard series full automatic vision measurement machine is with Full CNC close-loop axis motion control, using UWC 4000i series controller, servo motors and joystick, ensures stable and fast movement, increase the measuring accuracy and efficiency. Also the package solution for the control system offers stable performance of the machine, minimizing the maintenance.

UWC PAckage Solution

The full control system is embedded in the machine body, makes the machine structure smarter, and free from the large electronic cabinet, a small space or desk top is enough for the installation.

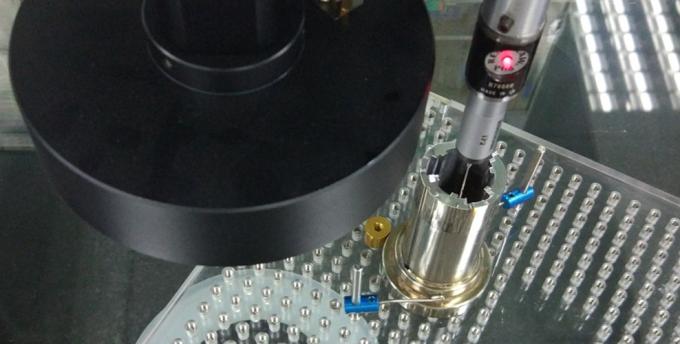

Standard series full automatic vision measurement machine is compatible with full series of Renishaw touch probes to achieve 2D 3D composite measuring, in addition of Sunnyoo or External Array 3D measuring software, users can achieve the 2D 3D measuring in the same coordinates system, even CAD digital model inputting is available.

Non-contact laser sensors are also available in the standard series, which offers fast measuring of the height, contour and flatness of the work pieces.

000 grade marble machine base and column, ensures stability, safety and reliability .

The working stage of the Standard series full automatic vision measurement machine is made of high performance aluminum alloy, which is light and with high rigidity, ensures the smooth and outstanding axis motion performance.

The Standard series full automatic vision measurement machine is capable to use on the production line, offers powerful measuring instrument for mass production.

Three axis are using precise cross guide way to ensure high accuracy and stability.

High resolution color CCD , combined with multiple lens and illumination solutions ensure the clear and precise image.

Equipped with high-performance linear scales, high accuracy and stability.

Manual zooming lens ,image magnification up to 18X~188X, also auto zoom lens are for option, users are able to create full automatic measuring program easily with the auto zoom function.

Auto zoom co-axial light lens for option

Parrameters

| Item | Standard 322 CNC | Standard 432 CNC | Standard 542 CNC | |

| Dimension(mm) | 650 x 550 x 935 | 800 x 700 x 1000 | 1100 x 800 x 1030 | |

| Measuring range | X | 300 | 400 | 500 |

| Y | 200 | 300 | 400 | |

| Z | 200 | 200 | 200 | |

| Working stage | Stage size | 460 x 360 | 560 x 460 | 660 x 560 |

| Glass size | 340 x 240 | 440 x 340 | 540 x 440 | |

| Max. loading | 25kg | 25kg | 25kg | |

| Image and measuring system | CCD | Industrial color 1/3″ CCD camera | ||

| Lens | Manual dented zoom lens 0.7 – 4.5X (Navitar zoom lens for option) | |||

| Magnification | 18 – 188 X | |||

| Field of view(mm) | 11.1 – 1.7 | |||

| Working distance | 92mm | |||

| Display resolution | 0.001mm | |||

| Measuring Accuracy(um) | Optical | E1x, E1y=3+L/200 | ||

| E1z=3.9+L/200 | ||||

| E2xy=3.0+L/150 | ||||

| Probe | E3=3.5+L/100 | |||

| Resolution | 1um, 0.5um for option | |||

| Operation mode | Integrated intelligent control(joystick, mouse, keyboard) | |||

| Illumination | Programmable LED surface ring light, 8 sections, parallel contour light | |||

| Power supply | 220V±10% AC 50Hz, resistance≦4 ohm ground should be required | |||

| Working environment | Temperature 18-24 °C, humidity 30 – 75%, avoiding vibration | |||

Compatible accessories

Illumination

4 sections surface ring LED light

8 sections surface ring LED light

40 sections surface ring LED light

40 sections color surface ring LED light

Lens

Manual dented zoom lens

Co-axial optical manual zoom lens

Auto zoom lens

Co-axial optical auto zoom lens

Probes

Renishaw MCP touch probe kits, probe measuring error <=0.75

Renishaw PH6+TP20 touch probe kits, probe measuring error <=0.35

Laser scanner

KEYENCE non-contact laser sensors series

Application in customers’ site