| Camera: | Industrial Grade 1/2″ Color CCD Camera | Magnification: | 33-195X |

|---|---|---|---|

| Driving System: | Full Close-loop CNC Control, AC Servo Motor, 3 Axis Automatic And Programmable, Joystick Control, Keyboard Control | Linear Scale Resolution: | 1um / 0.5um / 0.25um / 0.1um For Optional |

| Measuring Software: | Rational Vue 3D Composite Measuring Software |

3D Composite Vision Measurement Machine Fully-Automatic Programmable

Introduction

The Delicate series vision measurement machine designed and created by UNIMETRO, is a composite vision measurement machine. It is built based on advanced technology of optics, probing, laser sensor and motion control, which ensures the accuracy, repeatability and motion performance. The Delicate series is an outstanding device for accurate inspection, QC, and the production.

The Delicate series vision measurement machine is a high-quality composite measurement instrument with coordinates measuring and optical vision technology, which is sourced from German structure design.

Features

1. 000 grade granite machine base, working table and gantry, to ensure the structure stability of the machine during movement.

2. Close-loop motion control system, coordinated with the high-accuracy hardware , the machine axis positioning can be fast and accurate.

3. Renishaw linear scale embedded,to offer high measuring accuracy and stable performance.

4. Using original Panasonic servo motors to increase the movement speed, ragidity and stability.

5. High-accuracy linear guideway guarantees the accuracy and stability of the movement.

6. Multiple option for lens or cameras based on customers’ requirements, to satisfy different vision measuring requirement.

7. RationalVue 3D composite software available:

2D inspection software + 3D inspection software + CAD reversal software + Form analysing software + contour scanning software + SPC statistical software + off-line programming software + tolerance valuation Software.

Open Options

CCD optical lens – Different solution for option based on different measuring objects, in order to gain faster and more stable image based on different measuring requirements.

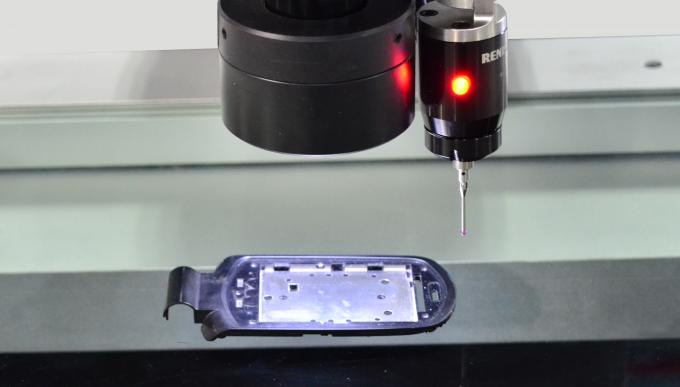

Touch probe – To achieve 3D measuring

Laser sensors – For height, depth and flatness non-contact measuring

Specification

| Model | Delicate 400 CNC | Delicate 500 CNC | Delicate 600 CNC | |

| Dimension (mm) | 1300*1100*1800 | 1400*1200*1800 | 1500*1300*1800 | |

| Measuring range (mm) | X | 400 | 500 | 600 |

| Y | 300 | 400 | 500 | |

| Z | 200 | |||

| Measuring accuracy (um) | 3+L/100 | 5+L/100 | ||

| Weight (KG) | 1800 | 2500 | 3000 | |

| Image and Measuring System | Camera | Industrial grade 1/2″ color CCD camera | ||

| Objective lens | Manual detented zoom lens/Autozoom lens 0.7-4.5X/Navitar lens for optional | |||

| Magnification | 33-195X | |||

| Vision field | 8.1-1.3 | |||

| Working distance | 108mm | |||

| Measuring resolution | 0.001mm | |||

| Linear scale resolution | 1um / 0.5um / 0.25um / 0.1um for optional | |||

| Driving System | Full close-loop CNC control, AC servo motor, 3 axis automatic and programmable, joystick control, keyboard control | |||

| Measuring software | Rational Vue 3D composite measuring software | |||

| Illumination | Programmable 8 sections ring LED for surface light, 40 sections ring LED for option, LED parallel contour light, co-axial light for option. | |||

| Power supply | 220V±10%(AC)50Hz, grounding with resistance≦4Ω is required | |||

| Working environment | Temperature: 18-24°C, Humidity: 30%-75%, Avoid vibration | |||

Application on customers’ site