| Place of Origin: | China |

|---|---|

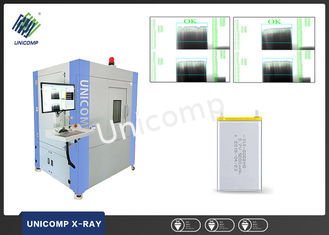

| Brand Name: | UNICOMP |

| Certification: | CE, FDA |

| Model Number: | AX8200 |

| Name: | Unicomp X-ray Inspection Machine | Application: | SMT, EMS,BGA, Electronics, CSP , LED , Flip Chip , Semiconductor |

|---|---|---|---|

| Intensifier: | 4″Image Intensifier | Monitor: | 22″LCD |

| System Magnification: | 600x | Power Consumption: | 0.8kW |

Metal X Ray Machine Solder reflow analysis for PCB / BGA / LED

X-ray detection technology for the SMT production testing means brought new changes, it can be said that it is the desire to further improve the level of production technology to improve the quality of production, and will soon find the circuit assembly failure as a breakthrough. It’s the best selection for the manufacturer.

| Item | Definition | Specs |

| System Parameters | Size | 1080(L)x1180(W)x1730(H)mm |

| Weight | 1150kg | |

| Power | 220AC/50Hz | |

| Power Consumption | 0.8kW | |

| X-ray Tube | Type | Closed |

| Max.Voltage | 90kV/100kV | |

| Max.Power | 8W | |

| Spot Size | 5μm | |

| X-ray System | Intensifier | 4″Image Intensifier |

| Monitor | 22″LCD | |

| System Magnification | 600x | |

| Detection Region | Max.Loading Size | 510mm x 420mm |

| Max.Inspection Area | 435mm x 385mm | |

| X-ray Leakage | < 1uSv/h | |

Object Stage Control

1. by the space bar to adjust stage speed: slow, constant and fast speed

2. Keyboard control X, Y, Z three-axis motion and inclined angle

3. The user can control the stage speed and angle programmatically

Full Automatic BGA Testing Procedures

1. A simple mouse click programming without the need for operator intervention on the component can detects each BGA automatically.

2. Automatic BGA test, accurately check the bridge, Welding, cold welding and void ratio of BGA.

3. Automatic BGA test repeatable test results in order to process control

4. The test results will be displayed on the screen and can be output to Excel to facilitate review and archiving

Inspection Images: