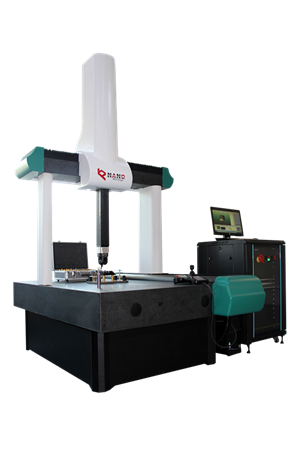

As one of the leading China CMM manufacturers and suppliers, We also provide sp25m, revo touch scanning head. It is here waiting for your contact.

1.SP25M

Scanning provides large amounts of data,which can be used to determine the ‘fitness for purpose’ of complex components. Where a number of features form functional fits with other parts, the form or shape of the feature is critical and a scanning sensor is most appropriate.

Specifications:

| Mounting | Renishaw’s autojoint: PH10M, PH10MQ or PH6 heads |

| Probe attributes | 3 axis analogue measurement (X, Y, Z) Pivoting motion in XY plane with translation in Z |

| Measurement range | ±0.5 mm (±0.02 in) deflection in all directions in all orientations |

| Overtravel range | ±X, ±Y = 2.0 mm (0.08 in) +Z = 1.7 mm (0.07 in) -Z = 1.2 mm (0.05 in) |

| Crash protection | X, Y, -Z via break-off of either module or stylus holder +Z via integral bump-stop design |

| Power supply | +12 V (±5%), -12 V (+10% / -8%), +5 V (+10% / +13%) DC at probe |

| Probe calibration | SP25M requires a non-linear, third-order polynomial calibration method |

2. REVO

REVO® is a revolutionary measuring head and multisensor probe system. Every process and feature in a REVO® system has been designed to enable users to achieve previously unobtainable levels of inspection.

Features:

a. Measure faster: up to 50 times faster surface speed than 3-axis scanning

b. Measure more points: 4000 points per second acquisition rate

c. Measure more features: infinite positioning for unparalleled flexibility

d. Measure surface finish: passive C-axis rotation for maximised feature access

e. Measure more accurately: with the REVO® tip-sensing probe